Delivering Smarter Solutions, Not Just Products

We go beyond assembly. With a strong focus on Value Analysis (VA) and Value Engineering (VE), we collaborate closely with our customers to optimize product design, reduce costs, and enhance functionality—without compromising on quality or reliability.

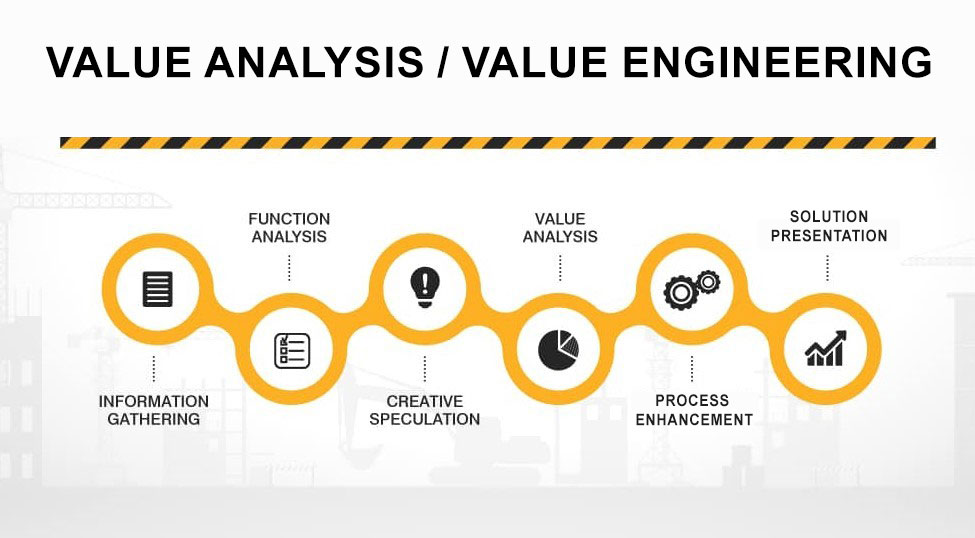

What is VA/VE?

Value Analysis is a systematic process applied to existing products to improve their value by either reducing cost or improving function.

Value Engineering applies the same principles during the product design phase—proactively identifying ways to enhance value before manufacturing begins.

Both processes are driven by a simple question:

How can we achieve the desired function at the lowest total cost?

Our VA/VE Approach Includes:

Design for Manufacturability (DFM)

- We evaluate your product’s design for ease of manufacturing—reducing complexity, part count, and assembly time.

Component Rationalization

- We analyze BOMs to identify alternate components, consolidated parts, or cost-effective sourcing strategies.

Process Optimization

- By refining assembly methods or leveraging automation, we reduce labor intensity and improve throughput.

Material Substitution

- We suggest alternative materials that meet functional requirements but offer savings or better availability.

Supply Chain Integration

- Our VA/VE recommendations are aligned with procurement and logistics strategies to ensure long-term viability.

Why Choose Our VA/VE Services?

- Collaborative Engineering: Our cross-functional teams work with your design, procurement, and quality teams.

- Proven Cost Savings: Our VA/VE programs have delivered up to XX% cost reductions for key clients.

- Faster Time to Market: Early-stage value engineering shortens development cycles and speeds up product launches.

- Sustainability: We help clients achieve greener designs with reduced waste and energy-efficient solutions.

Case Study Snapshot:

Customer Challenge: High-cost cable assembly in a medical device

Our Solution: Redesigned with standard connectors, improved layout for automated testing

Outcome: 28% cost reduction, 20% faster build time