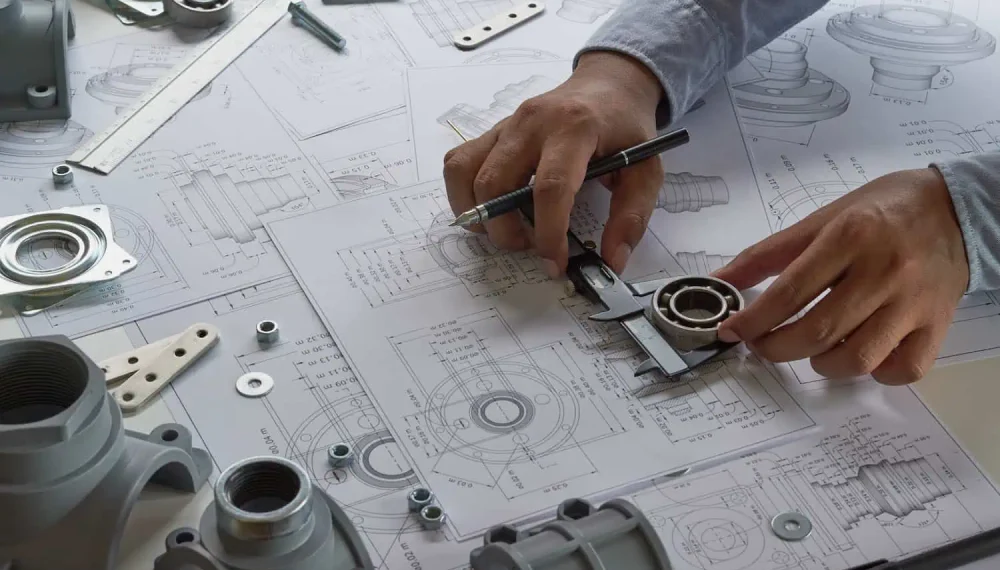

Design for Manufacturing (DFM) & Prototyping

Optimize Your Product Before It Hits the Production Line

At the heart of every successful box build lies a well-engineered design. Our Design for Manufacturing (DFM) and Prototyping services ensure your product is not only functional but also optimized for efficient, cost-effective, and scalable production.

Design for Manufacturing (DFM)

Our DFM process evaluates your product design from a manufacturing standpoint to identify potential challenges before they become costly issues. We collaborate with your engineering team early in the development cycle to:- Improve manufacturability: Ensure components and subassemblies are designed for ease of assembly, test, and integration.

- Reduce cost: Identify opportunities to simplify design, reduce part count, and choose cost-effective materials.

- Enhance reliability: Minimize risks related to component placement, thermal management, and structural integrity.

- Shorten lead times: Prevent delays by resolving design bottlenecks before production.

Prototyping Services

Before full-scale production, prototyping allows you to validate functionality, form, and fit. We offer rapid prototyping services tailored to your product’s requirements:

- Functional prototypes to test performance and identify design flaws.

- Visual prototypes for stakeholder reviews and market feedback.

- Pilot builds that simulate full production to evaluate assembly processes and supply chain readiness.

Our quick-turn prototyping enables you to iterate rapidly, reduce time to market, and move confidently into volume production.