Managing Supplier / Partner

Supplier Relationship Management (SRM)

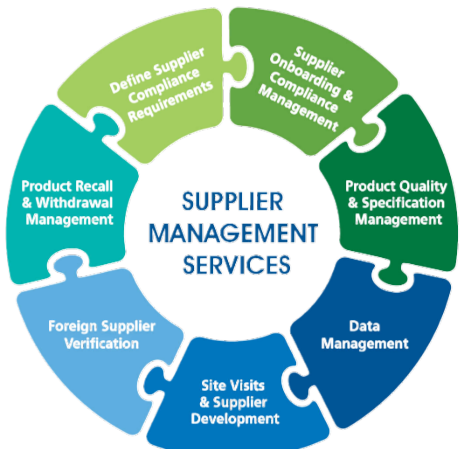

At the heart of our Box Build and EMS operations lies a strong, strategic Supplier Relationship Management (SRM) approach. We believe that long-term success in electronics manufacturing is built not just on technical expertise, but also on the strength of our supply chain partnerships.

Our Approach to SRM

We view our suppliers as key stakeholders in delivering quality, reliability, and innovation to our customers. Our SRM strategy is focused on:

Collaboration over Transaction

We move beyond traditional buyer-supplier relationships by fostering long-term, collaborative partnerships. This allows for greater transparency, improved forecasting, and shared innovation.

Quality First

Our approved supplier network is carefully vetted through a stringent qualification process, including audits, compliance checks, and performance metrics. We continuously monitor supplier performance to ensure consistent quality and adherence to industry standards.

Integrated Supply Chain Management

Leveraging real-time data and digital platforms, we maintain close coordination with our suppliers for materials planning, risk mitigation, and lead time optimization—ensuring smooth, efficient production for every project.

Sustainability and Ethics

We are committed to ethical sourcing and environmental responsibility. Our SRM framework includes ESG (Environmental, Social, and Governance) compliance requirements, aligning our suppliers with global standards and values.

Continuous Improvement

Through regular reviews, feedback loops, and joint problem-solving, we work with our suppliers to continuously enhance cost efficiency, product performance, and supply chain resilience.

Why It Matters

In the fast-paced EMS industry, agility and reliability are crucial. Our SRM model ensures that we are always aligned with the best suppliers—empowering us to deliver scalable, high-quality, and timely solutions for our customers, even in the face of market volatility.